Firmware compose is use a

PIC18F1320 microcontroller and write TPIC6C596 power shift which is a very

simple procedure. Only

four display mode and change from two display mode and a display speed

switching.

Tools

a. soldering

iron;

b. Hot

glue gun

c. Drill

d. 5mm

drill bit, drill a hole for LED

e. Art

designing Knife

Material

a. PIC18F1320

b. 18-pin

socket

c. TPIC6C596

shift register

d. 16-pin socket

e. 5mm

LED, 64 个, color does not matter, I use white

f.

3 pieces of 10kΩ, 1/4w resistor

g. 8

pieces of 220Ω resistors

h. 1

uF capacitor

i.

0.1uF capacitor

j.

x2 button

k. 5v,

1A DC power supply Circuit board

l.

Single stranded

m. Universal

circuit board

n. Acrylic

board

2. making framework

Parts of Frame illustration required

Wall is not perforated. Framework

is split up with four trapezoidal

Wall perpendicular to the frame surface

then assembled

A hole above is a DC power line, two holes below are for two buttons.

Switch drill I use 5/16 inch

drill bit, then use the art knife too close to the square hole processing, and

finally coated with black paint, so the switch is more covert friends.

I use a 5mm drill hole, this

should not be too precise.

Do not hurry to tear protective

film Acrylic mirror above, you need to mark where needs drill hole.

Like the features of CAD array, to

mark array into 8 * 8, and then also marked in the back of the acrylic mirror.

Find somewhere flat bench start

punching, required a little attention points before drilling is to ensure that

no particles or something else will scratch the mirror.

1. Install

LED bulbs

The next step is the

placement of the hole on mirror with acrylic LED light array.

8 * 8 LED array is controlled by

multiplexing, Each column is mainly on the

cathode of the LED and connected together, each line of the LED anodes are

connected together too. Use this

wiring method, a power supply connected to the first line and you can control a

single LED.

As shown above, using needle nose

pliers to bend the LED bulb two legs breaking

As the figure show above, on the left is the cathode, the right is the

anode, a closer look, not at a length of two

legs bent, which is to facilitate

the following wiring.

LED back is like the figure above

4. controller

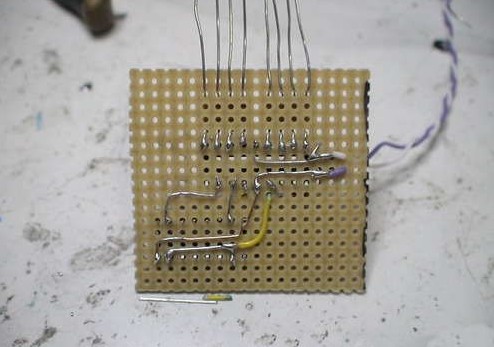

I was connected to the existing circuit board, in order to save

money, do not use any terminal or connector but directly welded connection of

the LED on the control circuit. Circuit

is not complicated, I am sure you can finish it by following schematic.

After welding circuit, do not hurry to connect chips, try using

a voltmeter to check where is short or open circuit. The

last step is to push button switch connected to the circuit board.

6 . controller connect

with LED array.

7. Firmware

Firmware should be in writing to the PIC on the forth step inside, and

then to put PIC mounted to the circuit board. Now job is done.

No comments:

Post a Comment